Understanding E10 Gasoline and Its Storage Challenges

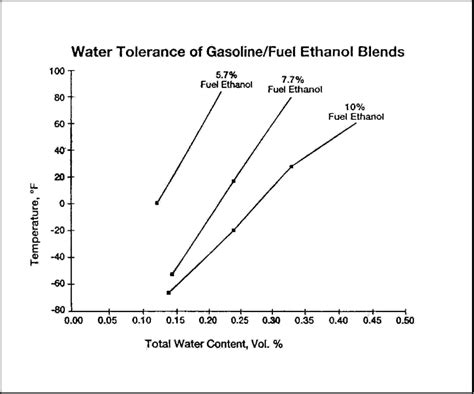

E10 gasoline, a blend of up to 10% ethanol and 90% petroleum, has become a standard fuel in many regions. While it offers some environmental benefits, its ethanol content presents unique challenges when it comes to long-term storage. Ethanol is hygroscopic, meaning it readily absorbs moisture from the air, and it can also cause phase separation, where the ethanol and water mixture separates from the gasoline, sinking to the bottom of the fuel tank. This separated layer is corrosive and can lead to significant engine and fuel system damage.

Moreover, gasoline itself degrades over time through oxidation, forming gummy deposits that can clog fuel filters and carburetors. These issues are exacerbated in E10 fuels, making proper stabilization crucial for any equipment that uses E10 and is stored for extended periods, such as lawnmowers, boats, classic cars, generators, or motorcycles.

Why Stabilizing E10 is Essential for Longevity

Ignoring the need for a fuel stabilizer in stored E10 gasoline can lead to a host of expensive problems. Without stabilization, fuel can become stale in as little as 30-60 days. Stale fuel can cause difficult starting, rough running, and even engine failure. The ethanol-water mixture is highly corrosive to metal components, particularly older fuel systems not designed for ethanol, and can dissolve plastics and rubber, leading to leaks and fuel system blockages.

A high-quality fuel stabilizer works by preventing the chemical reactions that lead to fuel degradation and by mitigating the negative effects of ethanol. It keeps the fuel fresh, prevents gum and varnish formation, and often includes corrosion inhibitors to protect metal parts from the ethanol-water mix.

Key Features of an Effective E10 Fuel Stabilizer

When selecting a stabilizer for E10 gasoline, look for products specifically formulated to address ethanol-related issues. Here are the crucial features:

- Ethanol Protection: The primary function. It should prevent phase separation and protect against the corrosive effects of ethanol on fuel system components.

- Anti-Oxidants: These prevent the oxidation of gasoline, which causes gum and varnish deposits to form, ensuring fuel lines and carburetors remain clear.

- Corrosion Inhibitors: Essential for protecting metal parts within the fuel tank and system from rust and corrosion, especially important with water absorption.

- Fuel System Cleaners: Some stabilizers include detergents to clean fuel injectors and carburetors, keeping the entire system operating efficiently.

- Long-Term Stability: A good stabilizer should keep fuel fresh for at least 12-24 months, ideal for seasonal equipment.

Top Recommended Stabilizer Types for E10

While brand names vary, the most reliable stabilizers for E10 often fall into these categories:

- Ethanol-Specific Stabilizers: Many modern stabilizers are explicitly marketed for ethanol-blended fuels. They contain advanced formulations to combat both gasoline degradation and ethanol’s hygroscopic and corrosive properties. Brands like STA-BIL 360 Protection or Lucas Safeguard Ethanol Fuel Conditioner are popular choices.

- Marine-Grade Stabilizers: Given the harsh, moist environments boats often operate in, marine fuel stabilizers are typically robust and excellent for E10 storage in any application. They offer superior water dispersion and corrosion protection.

- All-Purpose Stabilizers with Ethanol Claims: Standard fuel stabilizers (e.g., original STA-BIL) have been updated to address ethanol issues. Always check the product label to ensure it explicitly mentions protection against ethanol-related problems.

Always follow the manufacturer’s instructions for dosage and application, as these can vary significantly between products.

Applying Fuel Stabilizer Correctly

For the best results, add the fuel stabilizer to your E10 gasoline before storage, ideally with a fresh tank of fuel. Here’s a general guide:

- Add to Tank: Pour the recommended amount of stabilizer directly into the fuel tank.

- Top Up (if needed): For optimal results, fill the fuel tank to capacity with fresh E10 gasoline. A full tank minimizes air space, reducing condensation and oxygen exposure, which contribute to fuel degradation.

- Run the Engine: Start the engine and let it run for 5-10 minutes. This ensures the stabilizer circulates throughout the entire fuel system, including the fuel lines, carburetor, and injectors, protecting all components.

- Store: Turn off the engine and store the equipment in a cool, dry place.

This process ensures all parts of the fuel system are treated and protected against the effects of long-term storage with E10 gasoline.

Beyond Stabilizers: Best Practices for E10 Storage

While a good fuel stabilizer is crucial, combining it with other best practices will maximize the lifespan of your stored E10 gasoline and protect your equipment:

- Fill the Tank: As mentioned, a full tank reduces air space and the chance of condensation, which means less water for ethanol to absorb.

- Use Approved Containers: If storing fuel outside of equipment, use only approved, airtight fuel containers designed for gasoline storage. Ensure they are clean and free of rust or debris.

- Store in a Cool, Dry Place: Keep fuel containers and equipment in a stable temperature environment, away from direct sunlight and extreme heat or cold.

- Regular Checks: Periodically inspect stored fuel for signs of degradation (e.g., cloudy appearance, strong sour smell, visible separation). While stabilizers help, they don’t last forever.

- Consider Ethanol-Free Fuel (if available): For very long-term storage (over 1-2 years) or highly sensitive equipment, using ethanol-free gasoline with a stabilizer is the ultimate protection, although it can be harder to find.

Conclusion

E10 gasoline, while common, demands careful consideration for long-term storage due to its ethanol content. Investing in a high-quality fuel stabilizer specifically designed for ethanol-blended fuels is not just a recommendation, but a necessity to prevent costly repairs and ensure your engines start reliably after periods of inactivity. By understanding the challenges, choosing the right product, and applying it correctly alongside good storage practices, you can effectively protect your fuel and equipment for the seasons to come.