The widespread introduction of E10 fuel, containing up to 10% ethanol, has brought significant benefits, including reduced emissions and a degree of renewable energy use. However, for many vehicle owners, especially those with older cars or certain modern engines, E10 presents a unique set of challenges that can lead to engine damage if not properly addressed. Understanding these risks and knowing which fuel additives can mitigate them is essential for maintaining engine health and longevity.

Understanding E10 Fuel and Its Potential Issues

Ethanol is an alcohol with properties that differ significantly from pure gasoline. While it acts as an octane booster and a partial oxygenate, its hygroscopic nature (ability to absorb water) and solvent properties are the primary concerns for engine longevity. Ethanol can absorb moisture from the atmosphere, leading to water accumulation in the fuel tank and lines. This water can then cause corrosion and, in colder temperatures, freezing, which obstructs fuel flow.

Furthermore, ethanol is a strong solvent. Over time, it can degrade certain rubber and plastic components found in older fuel systems, such as fuel lines, seals, and gaskets, leading to leaks and fuel system failures. It can also loosen deposits and varnish built up over years in the fuel tank and lines, which then circulate and clog fuel filters and injectors. Modern engines are generally designed to be E10 compliant, but even they can benefit from additives that combat water absorption and maintain fuel system cleanliness.

How Ethanol Harms Engine Components

The damage caused by E10 fuel is multifaceted:

- Corrosion: Ethanol’s affinity for water, combined with its own corrosive properties, can lead to rust and corrosion of metal components within the fuel system, including the fuel tank, lines, and fuel pump.

- Material Degradation: Older fuel system components made from specific types of rubber or plastic can become brittle, crack, or dissolve when exposed to ethanol, leading to fuel leaks or blockages.

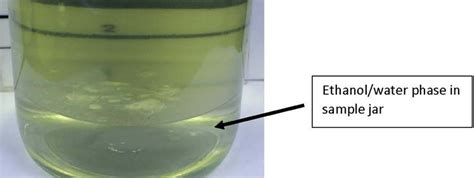

- Phase Separation: If enough water is absorbed, the ethanol and water can separate from the gasoline, forming a distinct layer at the bottom of the fuel tank. This ‘phase separation’ means the engine might draw in a water-ethanol mix, which can cause misfires, poor performance, and even engine damage.

- Reduced Lubricity: Ethanol has lower lubricity than gasoline, which can increase wear on fuel pumps and injectors not designed for its properties.

The Role of E10 Fuel Additives in Damage Prevention

Specialized E10 fuel additives are formulated to counteract these negative effects, providing comprehensive protection for your engine and fuel system. They typically combine several active ingredients to tackle different issues simultaneously.

1. Corrosion Inhibitors

These additives create a protective barrier on metal surfaces, preventing direct contact with corrosive elements like water and ethanol. They are crucial for safeguarding fuel tanks, lines, and injectors from rust and chemical degradation, which is especially important for vehicles with older, non-ethanol-resistant metal components.

2. Fuel Stabilizers and Water Dispersants

Fuel stabilizers prevent gasoline from degrading over time, which is particularly useful for vehicles stored for extended periods. More importantly, water dispersants emulsify any absorbed water, blending it harmlessly into the fuel so it can pass through the system and be combusted without causing phase separation or engine issues. This protects against rust and ensures consistent fuel quality.

3. Lubricity Enhancers

To combat the reduced lubricating properties of ethanol, these additives introduce components that restore lubricity to the fuel. This helps to reduce wear and tear on critical fuel system components like fuel pumps and injectors, extending their lifespan and maintaining optimal performance.

4. Fuel System Cleaners

Many E10 additives also contain powerful detergents that clean fuel injectors, carburetors, and intake valves. This prevents the buildup of carbon deposits that can hinder fuel flow and combustion efficiency. By keeping these components clean, additives help maintain optimal engine performance, fuel economy, and reduce harmful emissions.

Choosing the Right E10 Additive

When selecting an E10 fuel additive, look for products that offer a multi-functional approach, addressing corrosion, water management, lubrication, and cleaning. Reputable brands often clearly state their product’s benefits and compatibility. Consider the age and type of your vehicle; classic cars will require more robust protection against material degradation, while modern cars might primarily benefit from water dispersants and cleaning agents. Always follow the manufacturer’s dosage recommendations for the additive to ensure effective protection.

Conclusion: Essential Protection for Your Engine

E10 fuel is here to stay, and while it brings environmental advantages, its unique properties necessitate proactive engine protection. By regularly using a high-quality, multi-functional E10 fuel additive, you can effectively prevent the corrosion, material degradation, and performance issues associated with ethanol. This simple step can significantly extend the life of your fuel system and engine, ensuring reliable performance and peace of mind on the road.