Fuel degradation is a significant concern for anyone storing fuel long-term, from industrial facilities to individual users. It can lead to equipment damage, reduced efficiency, and costly downtime. Understanding the mechanisms of degradation and implementing preventive measures is crucial for maintaining fuel quality and operational reliability.

Understanding the Enemy: Causes of Fuel Degradation

Fuel is not static; it’s a complex blend of hydrocarbons and additives that can change over time. The primary culprits behind degradation include oxidation, water contamination, microbial growth, and temperature fluctuations. Each of these factors can accelerate the breakdown of fuel components, leading to the formation of sludge, gums, and acids, which can then clog filters, corrode fuel systems, and reduce engine performance.

Key Strategies for Preventing Fuel Degradation

Effective fuel storage begins with the right environment. Storing fuel in a cool, dark, and well-ventilated area minimizes thermal degradation and light exposure. Direct sunlight and high temperatures accelerate oxidation reactions, breaking down fuel molecules and forming undesirable byproducts. Maintaining a stable, lower temperature helps preserve the fuel’s chemical integrity.

Tank Cleanliness and Material: The storage tank itself plays a critical role. Tanks should be made of materials resistant to corrosion and regularly inspected for rust, scale, or sediment buildup. Regular cleaning of storage tanks prevents the accumulation of contaminants that can catalyze degradation reactions and harbor microbial life. Steel tanks, especially, require vigilant internal inspection for rust.

Water Management: The Silent Killer

Water is arguably the most detrimental contaminant in fuel storage. It promotes microbial growth (often called ‘fuel bug’), accelerates corrosion in tanks, and can lead to the formation of emulsions that reduce fuel efficiency and damage engines. Implementing a robust water management strategy is essential. This includes ensuring tanks are properly sealed to prevent rainwater ingress and regularly draining any accumulated water from the bottom of the tank, as water is denser than fuel.

The Role of Fuel Additives

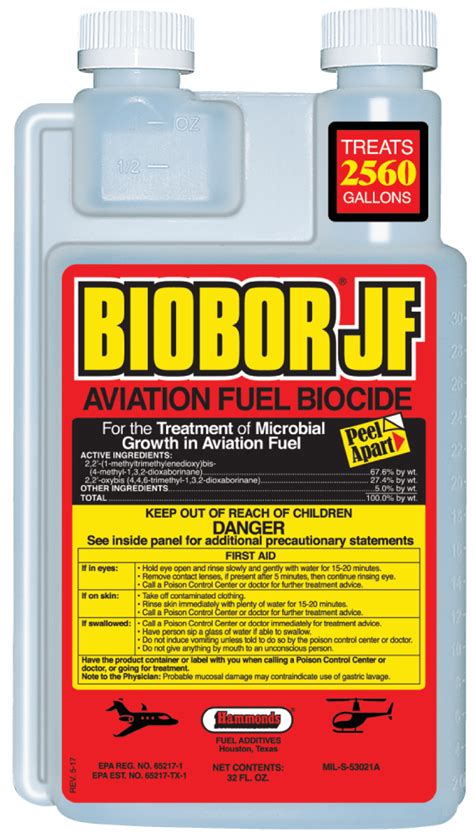

For long-term storage, fuel additives can be invaluable. Fuel stabilizers work by slowing down oxidation and preventing the formation of gums and varnishes, effectively extending the fuel’s shelf life. Biocides, on the other hand, are crucial for inhibiting the growth of bacteria, fungi, and yeasts that thrive at the fuel-water interface, preventing filter clogging and fuel system corrosion. Choose additives appropriate for your specific fuel type and storage duration.

Regular Monitoring and Testing

Proactive monitoring is key to preventing major issues. Regular visual inspections of fuel for discoloration or sediment are a good start. However, periodic professional fuel testing provides a comprehensive analysis of fuel quality, identifying potential issues like water content, microbial contamination, and oxidation levels before they become severe problems. Testing helps validate the effectiveness of your storage practices and allows for timely corrective actions.

Inventory Management: First-In, First-Out (FIFO)

While not always feasible for large-scale operations, implementing a “first-in, first-out” (FIFO) inventory system for fuel helps ensure that older fuel is used before it has a chance to significantly degrade. This minimizes the overall storage time for any given batch of fuel, promoting fresher fuel usage and reducing the need for extensive stabilization or treatment.

Conclusion

Preventing fuel degradation in storage is a multi-faceted approach requiring diligence and adherence to best practices. By controlling environmental factors, maintaining tanks, managing water, utilizing appropriate additives, and regularly monitoring fuel quality, you can significantly extend the lifespan of stored fuel, protect your equipment, and ensure reliable performance when it’s needed most. Investing in these preventive measures ultimately translates into substantial savings from avoiding costly repairs and fuel replacement, while also providing peace of mind.