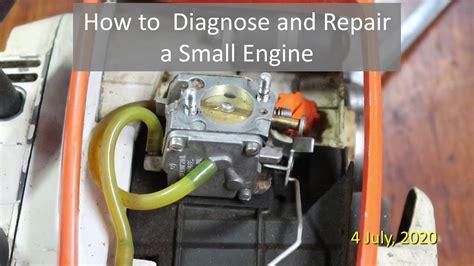

Small engines power the workhorses of our yards and workshops: lawnmowers, string trimmers, chainsaws, generators, and more. These machines often represent a significant investment, and keeping them running smoothly for years is a top priority for owners. A common debate among small engine enthusiasts revolves around fuel choice, specifically the use of ethanol-free gasoline. But is opting for the pricier, ethanol-free alternative truly worth the extra cost for the sake of engine longevity?

Understanding Ethanol in Gasoline

Ethanol, an alcohol-based additive, has been widely used in gasoline for several reasons. Primarily, it acts as an oxygenate, helping fuel burn more completely and reducing harmful emissions. It also serves as a renewable fuel source and can boost octane. Most conventional gasoline sold today contains up to 10% ethanol (E10), and sometimes even higher concentrations like E15 or E85. While beneficial for modern automotive engines designed to handle it, ethanol can spell trouble for older vehicles and, more notably, for small engines.

The Detrimental Effects of Ethanol on Small Engines

Small engines, unlike many modern car engines, were often not designed to tolerate ethanol. The problems stem from several key properties of ethanol:

- Water Absorption: Ethanol is hygroscopic, meaning it readily absorbs and attracts water from the atmosphere. This water can then separate from the gasoline, sinking to the bottom of the fuel tank and leading to rust and corrosion in metal components like fuel tanks, carburetors, and fuel lines.

- Corrosion and Material Degradation: Ethanol can be corrosive to certain metals and can also degrade plastic and rubber components commonly found in older fuel systems and small engines. Fuel lines can become brittle and crack, gaskets can fail, and carburetor parts can swell or disintegrate.

- Fuel System Clogging: As ethanol degrades, it can leave behind gummy deposits and varnish. These residues can clog fuel filters, tiny carburetor jets, and fuel lines, leading to poor engine performance, difficult starting, or complete engine failure. This issue is exacerbated when fuel sits for extended periods, such as during winter storage.

- Phase Separation: When water accumulates in ethanol-blended fuel, it can cause the ethanol and water to separate from the gasoline, forming a distinct layer at the bottom of the tank. This “phase separation” means the engine will then draw in a highly corrosive, water-rich ethanol mixture, causing severe damage.

The Case for Ethanol-Free Gasoline (E0)

Ethanol-free gasoline (often labeled E0) eliminates all the issues directly caused by ethanol. By using E0 fuel, small engine owners can expect:

- Reduced Corrosion and Degradation: Without ethanol, the risk of water absorption, phase separation, and the associated corrosion of metal parts is significantly lowered. Fuel lines and seals are less likely to degrade.

- Cleaner Fuel Systems: E0 fuel doesn’t leave behind the sticky, gummy deposits that clog carburetors and fuel injectors, especially during periods of inactivity. This leads to more reliable starting and consistent performance.

- Extended Engine Life: By protecting critical fuel system components from damage and ensuring clean fuel delivery, ethanol-free gasoline directly contributes to the overall longevity of the engine. Less maintenance and fewer costly repairs mean your equipment lasts longer.

Is the Extra Cost Justified?

Ethanol-free gasoline typically costs more per gallon than E10. This higher price point leads many to question its value. However, when considering the long-term health of your small engines, the cost difference can often be offset by several factors:

- Reduced Repair Costs: A single carburetor rebuild or replacement can easily cost more than the cumulative difference in fuel prices over several seasons. Preventing these common ethanol-related failures saves money.

- Increased Reliability: Equipment that starts easily and runs smoothly saves time and frustration. For professional landscapers or those who rely on their equipment regularly, reliability is paramount.

- Longer Equipment Lifespan: Extending the operational life of expensive equipment like generators, pressure washers, or high-end lawnmowers means delaying the need for costly replacements.

For seasonal equipment that sits for months, the benefits of E0 are even more pronounced, as ethanol’s degradation accelerates with time.

Alternatives and Best Practices If E0 Isn’t Available

If ethanol-free gas is not readily available in your area, or if the cost is truly prohibitive, there are still measures you can take to protect your small engines:

- Use Fuel Stabilizer: Always add a high-quality fuel stabilizer designed to combat ethanol’s effects to your fuel, especially before storing equipment for more than a few weeks. This helps prevent phase separation and gumming.

- Drain Fuel for Storage: For long-term storage (e.g., over winter), it’s best to completely drain the fuel tank and run the engine until it starves of fuel. This ensures no old, degrading fuel remains in the system.

- Frequent Fuel Rotation: Avoid letting fuel sit for too long. Buy smaller quantities and use them up relatively quickly.

- Check Manufacturer Recommendations: Always consult your equipment’s owner’s manual. Some newer small engines are designed to tolerate E10 better than older models.

Conclusion

For the longevity and reliable performance of your small engines, ethanol-free gasoline is undoubtedly a superior choice. While it comes with a higher upfront cost, the potential savings from reduced repairs, increased reliability, and extended equipment lifespan often make it a worthwhile investment. Preventing issues like corrosion, material degradation, and clogged fuel systems can save you significant time, money, and frustration in the long run. If you want your small engines to start on the first pull for years to come, E0 fuel is a wise decision.