For many small engine owners, the mention of E10 gasoline often brings a frown. This common fuel blend, containing up to 10% ethanol, has been widely available for years, yet concerns persist regarding its impact on the delicate components of lawnmowers, chainsaws, generators, and other outdoor power equipment.

Understanding E10 and Ethanol’s Properties

E10 gasoline is essentially a mix of 90% unleaded gasoline and 10% ethanol. Ethanol is an alcohol derived from plant materials, primarily corn, and is added to fuel for various reasons, including increasing octane and acting as an oxygenate to promote cleaner burning. However, its chemical properties are what make it a problematic component for small engines, particularly their carburetors.

The Hygroscopic Nature: Water Absorption

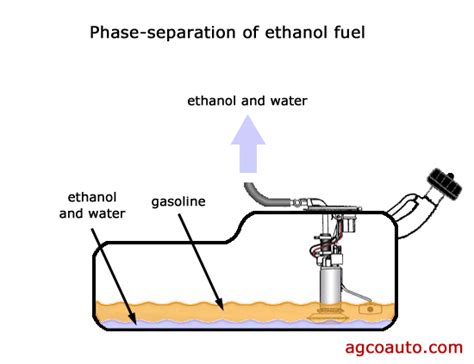

One of ethanol’s most critical properties is its hygroscopic nature – it readily absorbs and attracts water from the atmosphere. Unlike gasoline, which repels water, ethanol acts like a sponge. When water mixes with E10 fuel, especially in tanks that are not kept full or during periods of high humidity, the ethanol can absorb enough water to reach a saturation point.

Once saturated, the ethanol and water mixture separates from the gasoline, sinking to the bottom of the fuel tank. This phenomenon is known as “phase separation.” The water-ethanol mixture is highly corrosive and can cause rust in metal fuel tanks and components. When this separated layer is drawn into the carburetor, it leads to extreme lean conditions, rough running, and eventually, engine failure.

Ethanol’s Solvent Properties: Degradation and Clogging

Beyond water absorption, ethanol is also a strong solvent. This property can be a double-edged sword. On one hand, it helps keep fuel lines and injectors cleaner by dissolving varnish and carbon deposits. On the other hand, in older engines or those that have primarily run on non-ethanol fuel, it can dissolve existing sludge and varnish built up in the fuel tank and lines, sending these contaminants directly into the carburetor.

Small engine carburetors are designed with very fine jets and passages to precisely meter fuel. These tiny orifices are highly susceptible to clogging from even minute particles. The dissolved debris, along with the gummy residues that can form as ethanol evaporates, are prime culprits for blocked jets, causing erratic engine performance, difficult starting, and complete operational failure.

Material Compatibility Issues

Many older small engines were manufactured before E10 became widespread. Their fuel systems, including seals, gaskets, fuel lines, and carburetor components (like O-rings and diaphragms), were often made from materials that are not resistant to ethanol.

- Rubber and Plastic Degradation: Ethanol can cause these materials to dry out, crack, swell, or become brittle. This leads to fuel leaks, air leaks into the fuel system, and improper fuel delivery, all of which directly affect carburetor function.

- Corrosion of Metals: While most modern engine components are built to resist ethanol, older brass, aluminum, and zinc parts found in carburetors can be susceptible to corrosion, especially when exposed to the water-ethanol mixture from phase separation.

Protecting Your Small Engine from E10 Damage

While the risks are real, there are effective strategies to mitigate the potential harm of E10 gasoline to your small engine carburetor:

- Use Ethanol-Free Fuel (E0): Whenever possible, opt for gasoline explicitly labeled as ethanol-free. This is the surest way to avoid all ethanol-related issues.

- Employ a High-Quality Fuel Stabilizer: For E10 fuel, use a stabilizer specifically formulated to combat ethanol’s effects. These additives help prevent phase separation and keep fuel fresh for longer periods. Follow product instructions carefully.

- Drain Fuel for Storage: If you’re storing equipment for an extended period (e.g., winterizing a lawnmower), drain the fuel tank and run the engine until it stops from lack of fuel. This ensures the carburetor is empty and dry, preventing gumming and corrosion.

- Keep Fuel Tanks Full: For equipment in regular use, keeping the fuel tank full minimizes the air space available for moisture to condense and be absorbed by ethanol.

- Regular Maintenance: Periodically inspect fuel lines for cracks or swelling. If you suspect an issue, clean the carburetor or have it serviced by a professional. Replace fuel filters regularly.

- Consider Ethanol-Resistant Components: For frequently used equipment, it might be worthwhile to upgrade older fuel lines, gaskets, and O-rings to modern, ethanol-resistant versions.

Conclusion

The answer to whether E10 gasoline harms small engine carburetors is a resounding “yes,” especially without proper precautions. Its hygroscopic nature leads to corrosive phase separation, and its solvent properties can clog delicate jets. However, with diligent fuel management, the use of appropriate stabilizers, and consistent maintenance, you can significantly reduce the risk of damage and ensure your small engines run reliably for years to come.