Understanding the Threat: Ethanol and Your Small Engine

Ethanol, commonly blended into gasoline as E10 (10% ethanol), has become a pervasive component of modern fuel. While it serves as an oxygenate and octane booster, its properties pose significant challenges for small engines found in lawnmowers, chainsaws, generators, and other outdoor power equipment. Unlike car engines designed to handle ethanol, older or simpler small engines are particularly vulnerable to its detrimental effects, leading to costly repairs and reduced lifespan.

Why Ethanol Fuel Damages Small Engines

The primary issues with ethanol in small engines stem from its chemical properties:

Water Absorption (Hydroscopic Nature)

Ethanol is hydroscopic, meaning it readily absorbs and attracts water from the atmosphere. This can lead to water accumulating in the fuel tank, especially during storage or in humid conditions. Water in the fuel system can cause rusting and corrosion of metal components.

Material Degradation

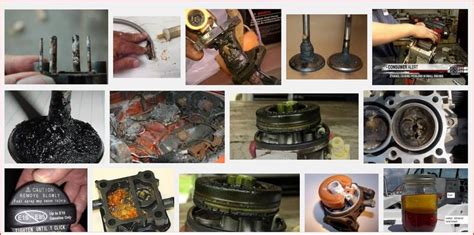

Many older small engine fuel systems were designed with rubber and plastic components (fuel lines, gaskets, carburetor parts) that are not compatible with ethanol. Ethanol acts as a solvent, causing these materials to soften, swell, become brittle, or even dissolve over time. This leads to fuel leaks, clogs, and carburetor malfunctions.

Corrosion

Ethanol can corrode aluminum and other metals found in carburetors and fuel pumps, particularly when water is present. This corrosion creates deposits that can block fuel jets and passages.

Phase Separation

When ethanol-blended fuel absorbs enough water, the ethanol and water mixture separates from the gasoline and sinks to the bottom of the fuel tank. This “phase separation” leaves behind a lower-octane gasoline on top and a highly corrosive, water-rich ethanol mixture at the bottom, which is then drawn into the engine, causing severe damage.

Effective Strategies to Protect Your Small Engine

Preventing ethanol damage is crucial for the longevity and reliable operation of your equipment. Here are the most effective strategies:

1. Use Non-Ethanol or Ethanol-Free Fuel

The simplest and most effective solution is to avoid ethanol entirely. Many gas stations now offer “pure gas” (E0) or ethanol-free gasoline, often advertised for marine or small engine use. Alternatively, premium pre-mixed fuels specifically designed for small engines (e.g., TruFuel, VP Small Engine Fuel) are available in cans. These fuels are typically ethanol-free, stabilized, and have a long shelf life, making them ideal for equipment used intermittently.

2. Employ Fuel Stabilizers and Ethanol Treatments

If non-ethanol fuel isn’t readily available, a high-quality fuel stabilizer designed to combat ethanol issues can provide significant protection. Look for products that specifically address water absorption, phase separation, and provide corrosion inhibitors. Add the stabilizer directly to the fuel tank according to manufacturer instructions every time you fill up, especially before long-term storage.

3. Practice Proper Fuel Storage

- Use Fresh Fuel: Only purchase as much fuel as you expect to use within a month or two. Stale fuel, especially ethanol-blended fuel, degrades quickly.

- Seal Containers: Store fuel in tightly sealed, approved containers to minimize exposure to air and moisture.

- Cool, Dry Place: Keep fuel containers in a cool, dry place, away from direct sunlight and extreme temperature fluctuations.

4. Drain Fuel for Long-Term Storage

For equipment that will be stored for more than 30 days (e.g., winterizing a lawnmower), it’s best to completely drain the fuel system. Run the engine until it runs out of fuel to ensure the carburetor is dry. This prevents stale fuel, phase separation, and ethanol corrosion from occurring while the engine is idle.

5. Regular Maintenance

Periodically inspect fuel lines, filters, and carburetor components for signs of wear, cracking, or swelling. Replace any damaged parts promptly. A clean fuel filter is vital to prevent contaminants from reaching the carburetor.

Conclusion

While ethanol-blended fuels are a common reality, they don’t have to be a death sentence for your small engines. By understanding the risks and implementing proactive measures—primarily using ethanol-free fuel or quality stabilizers, and practicing diligent fuel management—you can significantly extend the life of your equipment, ensure reliable starts, and avoid costly repairs. Prioritize prevention to keep your small engines running smoothly for years to come.