Understanding the Threat: Water in Fuel

Water and fuel are an incompatible mix, yet water contamination in fuel systems is a surprisingly common problem for vehicles, generators, and industrial equipment. Whether you operate a diesel engine, a gasoline vehicle, or a marine craft, the presence of water in your fuel can lead to a cascade of issues, from minor performance hiccups to catastrophic engine failure. Understanding how water gets into fuel and, more importantly, how to detect and eliminate it, is essential for maintaining operational efficiency and avoiding costly repairs.

This article will guide you through the various ways water infiltrates fuel, the tell-tale signs of contamination, and the most effective strategies for removal and prevention, ensuring your engine runs smoothly and reliably.

The Detrimental Effects of Water in Fuel

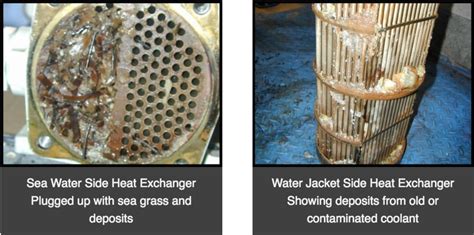

The impact of water in fuel extends far beyond simply reducing combustion efficiency. Water, being denser than fuel, typically settles at the bottom of the tank, where it can cause a range of severe problems. Firstly, it promotes rust and corrosion within the fuel tank, lines, and vital engine components like fuel injectors and pumps. These corrosive particles can then circulate, causing further damage.

Secondly, water diminishes the lubricity of fuel, particularly diesel, leading to premature wear on high-precision components. It also creates an ideal breeding ground for microbial growth, often referred to as ‘diesel bug’ – a sludge-like substance that clogs fuel filters and lines. In freezing temperatures, water can turn into ice crystals, blocking fuel lines and filters entirely, preventing fuel flow and leading to engine shutdown. Finally, water vaporizes explosively in the combustion chamber, leading to power loss, rough idling, and potentially damaging engine parts over time.

Common Sources of Water Contamination

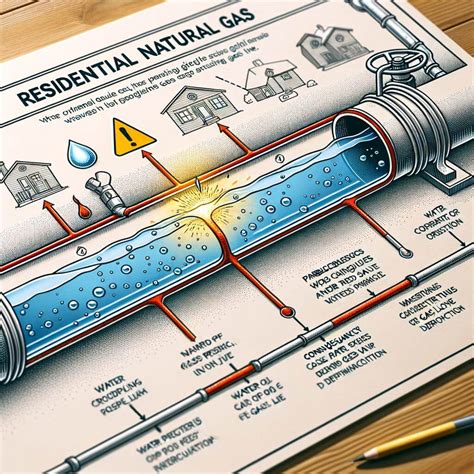

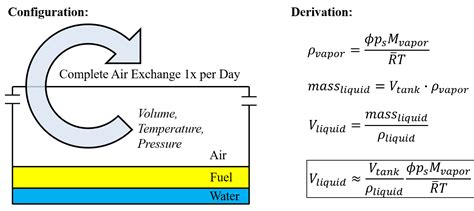

Water can find its way into your fuel system through several avenues. One of the most common is condensation. As fuel tanks, both in vehicles and bulk storage, cool down overnight or with changing temperatures, moisture from the air condenses on the tank walls and drips into the fuel. This problem is exacerbated when tanks are kept partially full, leaving more air space for condensation to occur.

Another significant source is contaminated fuel supply. Water can be introduced during the refining, transportation, or storage process at the fueling station. Improperly sealed fuel caps or vents, especially in humid or rainy environments, can also allow water ingress. Lastly, neglecting regular maintenance, such as not draining water separators, contributes to water accumulation over time.

Detecting Water in Your Fuel System

Early detection is key to mitigating the damage caused by water in fuel. Several methods can help identify its presence:

- Visual Inspection: If you can access your fuel tank or a sample, look for cloudiness, haziness, or distinct layers. Water, being heavier, will usually settle at the bottom or appear as droplets.

- Water Separator/Fuel Filter Bowls: Many modern diesel engines, and some gasoline ones, are equipped with a fuel filter/water separator that has a transparent bowl at the bottom. Visually inspect this bowl for any accumulated water, which will appear as a separate layer below the fuel.

- Water-Finding Paste: A special paste, applied to a dipstick, can be used to check for water in fuel tanks. The paste changes color upon contact with water, indicating the presence and depth of water at the bottom of the tank.

- Performance Issues: Misfires, loss of power, rough idling, excessive smoke from the exhaust, or frequent clogging of fuel filters can all be symptoms of water contamination.

Effective Solutions: Removing Water from Fuel

Once detected, addressing water in fuel promptly is crucial. The approach depends on the amount of water and the type of system:

- Draining Water Separators: The simplest and most common method for small amounts of water is to regularly drain the water separator. Most have a drain cock or valve at the bottom.

- Draining the Fuel Tank: For significant water accumulation, it may be necessary to drain the entire fuel tank. This is often best performed by a professional, as it involves safely disposing of contaminated fuel.

- Fuel Additives: Certain fuel additives can help. Demulsifiers break the emulsion of fuel and water, allowing the water to separate and be drained. Dispersants, often found in ‘gas-line antifreeze’ products, help small amounts of water mix with fuel so it can pass harmlessly through the combustion system. Use these sparingly and according to manufacturer instructions, as excessive use can sometimes harm fuel system components.

- Professional Fuel Polishing: For large fuel storage tanks or severe contamination, professional fuel polishing services use specialized filtration systems to remove water, sediment, and microbial growth, restoring fuel quality.

Preventing Future Water Contamination

Prevention is always better than cure. By adopting a few simple practices, you can significantly reduce the risk of water in your fuel:

- Keep Tanks Full: Whenever possible, keep your fuel tank full, especially during periods of temperature fluctuation or extended storage. This minimizes the air space available for condensation.

- Source Quality Fuel: Purchase fuel from reputable suppliers who maintain clean tanks and adhere to proper fuel handling procedures.

- Regular Maintenance: Adhere to your vehicle’s maintenance schedule, which typically includes inspecting and replacing fuel filters and regularly draining water separators.

- Inspect Fuel Caps and Seals: Ensure your fuel cap is properly sealed and that any vents are functioning correctly to prevent water ingress from rain or splashes.

- Proper Storage for Bulk Fuel: If you store fuel in bulk, ensure tanks are properly maintained, regularly inspected for water, and kept in a cool, dry place.

Keep Your Engine Running Clean

Water in fuel is a persistent adversary to engine health and performance. From accelerating corrosion and encouraging microbial growth to causing immediate operational failures, its presence poses a significant threat. However, by understanding the sources of contamination, diligently employing detection methods, and implementing timely corrective actions alongside robust preventative measures, you can safeguard your fuel system and ensure your engine continues to operate reliably and efficiently.

Regular vigilance and adherence to best practices will not only save you from costly repairs but also extend the life of your valuable equipment, keeping it running smoothly for years to come.