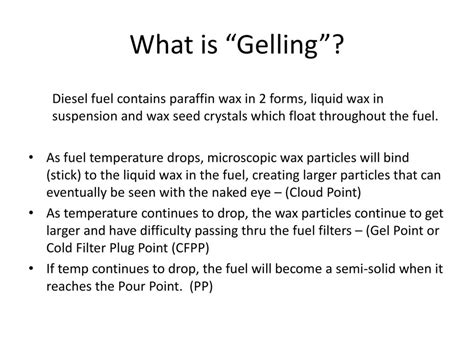

Winter weather brings unique challenges for diesel vehicle owners, with one of the most critical being diesel fuel gelling. When temperatures drop, the paraffin wax naturally present in diesel fuel can solidify, turning the fuel into a gel-like substance. This process, known as gelling, clogs fuel filters and lines, preventing fuel from reaching the engine and potentially leaving you stranded. Understanding how to prevent this common winter woe is essential for reliable operation.

Understanding Diesel Gelling and Its Impact

Diesel fuel gelling occurs in two main stages: the cloud point and the pour point. The cloud point is the temperature at which wax crystals begin to form in the fuel, making it appear cloudy. While this doesn’t immediately stop fuel flow, these crystals can begin to clog fuel filters. The pour point is the temperature at which the fuel thickens to the point where it will no longer pour, effectively halting fuel flow entirely. The severity of gelling depends on the fuel’s composition and the ambient temperature, making proactive prevention vital.

The First Line of Defense: Winterized Fuel

One of the simplest yet most effective ways to prevent gelling is to use ‘winterized’ or ‘winter blend’ diesel fuel. Fuel suppliers in colder climates adjust the fuel’s composition during winter months by blending in kerosene or using specific refining processes to lower its cloud and pour points. Always try to fill up at reputable stations that are likely to carry appropriate fuel for the season and region. Be cautious when traveling from warmer to colder climates; you may need to add an anti-gel additive if you can’t access winterized fuel immediately.

Fuel Additives: Your Best Ally

Anti-gel fuel additives are specially formulated chemicals that modify the structure of the wax crystals as they form, preventing them from growing large enough to clog filters. They are a highly effective preventative measure, especially when combined with winterized fuel. It’s crucial to add these additives before the fuel reaches its cloud point, ideally when refueling or at least several hours before extreme cold sets in, to allow for proper mixing. Follow the manufacturer’s instructions carefully for dosage.

Maintaining Your Vehicle’s Fuel System

A well-maintained fuel system is less susceptible to gelling issues. Regular maintenance includes:

- Fuel Filter Replacement: Clogged or dirty fuel filters can exacerbate gelling problems, as even small wax crystals will find it easier to block a filter that’s already partially obstructed. Replace your fuel filters as recommended by your vehicle manufacturer, or more frequently in harsh winter conditions.

- Fuel Heaters: Many modern diesel vehicles, especially trucks, come equipped with factory-installed fuel heaters that warm the fuel before it reaches the filter. Ensure these systems are in good working order. Aftermarket fuel heaters are also available and can provide an extra layer of protection.

- Water Separator Draining: Water in the fuel system can freeze and contribute to blockages. Regularly drain your fuel/water separator, especially in winter.

Smart Fuel Storage and Handling

If you store diesel fuel for extended periods, proper storage is paramount to prevent gelling and contamination:

- Keep Tanks Full: A full fuel tank reduces the amount of air space, minimizing condensation that can introduce water into the fuel.

- Use Clean Storage: Store fuel in clean, dry containers to prevent contamination.

- Consider Heated Storage: If possible, store vehicles or fuel tanks in a heated garage or shed overnight when extreme cold is expected.

Additional Preventative Measures

- Parking Indoors: If you have access to a garage, parking your diesel vehicle indoors overnight can keep the fuel temperature above its cloud point.

- Block Heaters: While primarily for engine starting, a block heater can indirectly help by keeping the engine bay warmer, which can slightly increase the temperature of fuel lines and filters.

- Insulate Fuel Lines: In extremely cold environments, some operators choose to insulate fuel lines to help maintain fuel temperature.

Conclusion

Preventing diesel fuel gelling in winter requires a multi-faceted approach. By consistently using winterized fuel, integrating high-quality anti-gel additives, ensuring your fuel system is well-maintained, and practicing smart fuel storage, you can significantly reduce the risk of gelling and ensure your diesel vehicle remains reliable throughout the coldest months. Don’t wait for the first deep freeze to take action; proactive prevention is key to a trouble-free winter.