Understanding the Challenge of Ethanol Fuel Degradation

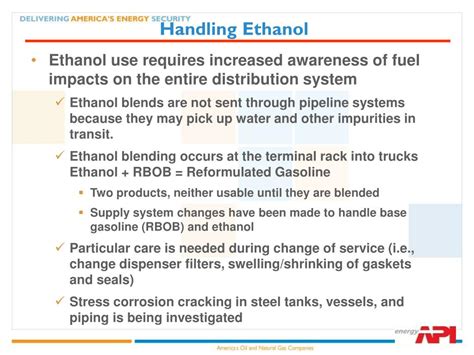

Ethanol-blended fuels, common in modern vehicles, offer certain benefits but also present unique challenges, particularly regarding their stability and propensity to degrade over time. Unlike pure gasoline, ethanol is hygroscopic, meaning it readily absorbs water from the atmosphere. This water absorption is the primary catalyst for a cascade of issues that can lead to significant engine and fuel system damage if not properly managed.

The degradation process typically begins with water absorption, leading to ‘phase separation’ where the ethanol and absorbed water separate from the gasoline and settle at the bottom of the fuel tank. This water-ethanol mixture is highly corrosive and can damage fuel lines, pumps, and carburetors, especially those made from older materials not designed for ethanol. Furthermore, ethanol can act as a solvent, loosening deposits and contaminants in the fuel system which can then clog filters and injectors. Oxidation, gum formation, and microbial growth can also accelerate in the presence of water and oxygen, further compromising fuel quality.

Key Strategies for Preventing Ethanol Fuel Degradation

Effective prevention involves a multi-pronged approach, focusing on storage, fuel additives, and regular maintenance.

1. Proper Fuel Storage

Storage is perhaps the most critical factor in preventing ethanol fuel degradation. Minimize the fuel’s exposure to air and moisture:

- Use Airtight Containers: Always store fuel in sealed, approved fuel containers to prevent atmospheric moisture from being absorbed. For vehicle or equipment tanks, ensure filler caps are tightly sealed and O-rings are in good condition.

- Keep Tanks Full: For equipment or vehicles that will be stored for an extended period, it’s often recommended to fill the fuel tank completely. A full tank leaves less air space for moisture to condense and be absorbed by the ethanol.

- Avoid Vented Tanks: For long-term storage, avoid highly vented tanks in humid environments if possible, as these allow more air and moisture exchange.

2. Utilize High-Quality Fuel Stabilizers

Fuel stabilizers are essential, especially for fuel that will sit for weeks or months. Look for stabilizers specifically designed for ethanol-blended fuels:

- Water Dispersants: Many stabilizers contain agents that help disperse any absorbed water throughout the fuel, preventing phase separation.

- Corrosion Inhibitors: These additives protect metal components from the corrosive effects of ethanol and water.

- Antioxidants: They slow down the oxidation process that leads to gum and varnish formation, keeping fuel fresh longer.

- Follow Instructions: Always add the stabilizer to fresh fuel, preferably when filling the tank, and follow the manufacturer’s recommended dosage. Run the engine for a few minutes after adding to ensure the treated fuel circulates throughout the system.

3. Regular Fuel System Maintenance

Proactive maintenance can mitigate the effects of degradation and catch problems early:

- Inspect for Water: Periodically check fuel filters and sumps for signs of water accumulation, especially in boat or outdoor equipment tanks.

- Replace Fuel Filters: Ethanol can loosen deposits, leading to clogged filters. Regular filter replacement is crucial.

- Ensure Ethanol-Compatible Components: If you own older equipment, ensure that all fuel system components (hoses, gaskets, seals) are rated for ethanol compatibility. Upgrade non-compatible parts to prevent premature failure.

4. Use Fresh Fuel

Ethanol-blended fuels have a shorter shelf life than pure gasoline. The simplest prevention method is to use fresh fuel and avoid long-term storage:

- Buy Only What You Need: Purchase fuel in quantities that can be used within a few weeks, especially for small engines or seasonal equipment.

- Rotate Stock: If you store fuel, use the oldest fuel first and replenish with fresh fuel.

Conclusion

Preventing ethanol fuel degradation is essential for the longevity and reliable performance of any engine, particularly those in small equipment, recreational vehicles, and boats that experience periods of inactivity. By understanding how ethanol reacts with moisture and taking proactive steps—such as proper storage, consistent use of fuel stabilizers, and vigilant fuel system maintenance—you can significantly extend fuel life, prevent costly repairs, and ensure your engines run smoothly for years to come.