For many owners of classic lawnmowers, vintage chainsaws, or older outboard motors, the question of fuel choice has become increasingly complex. The widespread adoption of E10 gasoline, containing up to 10% ethanol, has raised alarms regarding its compatibility with the materials found in small engines manufactured before the ethanol blend became standard. Understanding the potential risks and how to mitigate them is crucial for preserving the life and performance of these cherished machines.

Understanding E10 Fuel and Ethanol’s Role

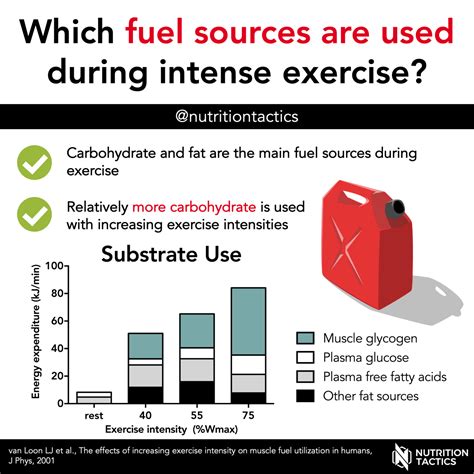

E10 fuel is a blend of gasoline and up to 10% ethanol, an alcohol derived from plant materials like corn. It was introduced to increase octane, reduce emissions, and extend fuel supplies. While beneficial for newer vehicles designed with ethanol-resistant components, older small engines, often manufactured before the widespread use of ethanol, were not built to withstand its unique chemical properties.

The Corrosive and Solvent Nature of Ethanol

Ethanol is hygroscopic, meaning it readily absorbs and attracts water. This water absorption can lead to phase separation within the fuel tank, where water and ethanol separate from the gasoline, sinking to the bottom. This water-rich layer can then cause corrosion in metal components, especially aluminum and steel, which are common in older carburetors and fuel tanks. Beyond water absorption, ethanol is also a powerful solvent.

Its solvent properties are particularly problematic for rubber and plastic components. Over time, ethanol can degrade, soften, or even dissolve certain types of rubber seals, gaskets, fuel lines, and plastic floats found in older fuel systems. This degradation leads to leaks, blockages, and overall fuel system failure.

Common Engine Components Vulnerable to E10

Several parts of an older small engine’s fuel system are particularly susceptible to ethanol damage:

- Fuel Lines: Older rubber fuel lines can become brittle, crack, or swell, leading to leaks and fuel delivery issues.

- Gaskets and O-rings: Carburetor gaskets and seals can deteriorate, causing air leaks, fuel leaks, and improper fuel-air mixture.

- Carburetor Components: Plastic floats can absorb ethanol and lose buoyancy, while aluminum and zinc alloy parts can corrode. Small passages within the carburetor can also become clogged with dissolved debris from degraded fuel lines or separated fuel.

- Fuel Tanks: Steel tanks can rust, and some plastic tanks may degrade.

- Fuel Filters: While not directly damaged by ethanol, fuel filters can quickly clog with the debris and gunk dislodged by ethanol’s solvent action.

Signs of Ethanol-Related Engine Trouble

If you’re using E10 fuel in an older small engine, watch out for these symptoms:

- Difficulty starting or rough idling.

- Engine surging or dying unexpectedly.

- Fuel leaks around the carburetor or fuel lines.

- Visible cracks or swelling on fuel lines.

- A milky substance in the fuel tank (indicating phase separation).

- Reduced power or poor performance.

Mitigating E10 Risks for Older Small Engines

While avoiding E10 entirely is the surest way to prevent issues, it’s not always practical. Here are strategies to protect your older small engine:

- Use Non-Ethanol Fuel: Whenever possible, opt for pure gasoline (often premium) or specialized small engine fuels that are explicitly ethanol-free. These are available at some gas stations or power equipment stores.

- Fuel Stabilizers: Always use a high-quality fuel stabilizer designed to combat ethanol’s effects, especially when storing the engine. Stabilizers can help prevent phase separation and keep fuel fresh.

- Drain Fuel for Storage: If an engine will be stored for more than a month, it’s best to drain the fuel tank and run the carburetor dry to prevent stale fuel and ethanol damage.

- Upgrade Components: Consider replacing old rubber fuel lines, gaskets, and carburetor components with ethanol-resistant (Viton or equivalent) parts. Many aftermarket kits are available.

- Regular Maintenance: Frequently check fuel lines for degradation, clean carburetors, and replace fuel filters.

Conclusion

While E10 fuel can present significant challenges for older small engines, understanding its properties and implementing preventative measures can greatly extend the life and reliability of your equipment. By choosing ethanol-free fuel when available, utilizing fuel stabilizers, performing regular maintenance, and upgrading vulnerable components, you can continue to enjoy your classic machines without succumbing to the common pitfalls of ethanol degradation.