Understanding Fuel Degradation and Its Impact

Storing fuel, whether for emergency generators, lawn equipment, or classic cars, comes with a critical challenge: degradation. Over time, gasoline and diesel can break down, lose their potency, and even damage engines. This process isn’t just an inconvenience; it can lead to costly repairs and unreliable equipment when you need it most. Understanding the causes of fuel degradation is the first step toward effective prevention.

Fuel degradation primarily occurs due to oxidation, microbial contamination, and water absorption, especially with ethanol-blended fuels. Exposure to air, moisture, and temperature fluctuations accelerates these processes, leading to gumming, varnish buildup, and phase separation.

Essential Strategies for Preventing Fuel Breakdown

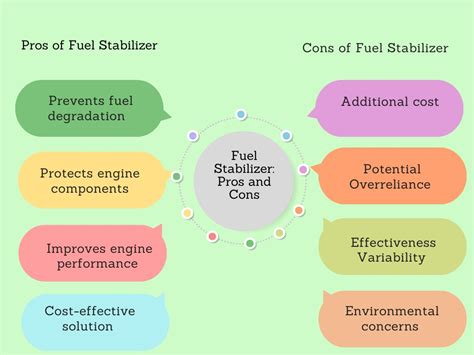

1. Utilize High-Quality Fuel Stabilizers

Perhaps the most effective and straightforward method to combat fuel degradation is the use of a reputable fuel stabilizer. These additives work by preventing oxidation and corrosion, keeping fuel fresh for extended periods. They are particularly crucial for gasoline, which can begin to degrade in as little as 30 days without treatment. Always follow the manufacturer’s instructions for mixing ratios and treatment duration.

For diesel, stabilizers often include biocides to prevent microbial growth (diesel bug) and dispersants to keep sediment suspended and prevent filter clogging. Choosing a stabilizer specific to your fuel type (gasoline or diesel) is paramount for optimal results.

2. Store Fuel in Approved, Airtight Containers

The container itself plays a significant role. Always use opaque, approved fuel containers made from materials like high-density polyethylene or metal that resist corrosion. Opaque containers block sunlight, which can accelerate degradation. Ensure the container is completely sealed to prevent air and moisture from entering. Air contains oxygen, a primary driver of oxidation, while moisture can lead to water contamination and microbial growth.

Additionally, storing fuel in a cool, dark, and dry environment is critical. Extreme temperature fluctuations can cause condensation inside the tank, introducing water into the fuel. A stable, moderate temperature helps maintain fuel integrity.

3. Minimize Air Space (Top Off Tanks)

When storing fuel for long periods, it’s often recommended to fill the storage tank or container as full as possible. This minimizes the air space above the fuel, thereby reducing the amount of oxygen available to react with the fuel. Less oxygen means slower oxidation and less opportunity for condensation to form inside the tank as temperatures change.

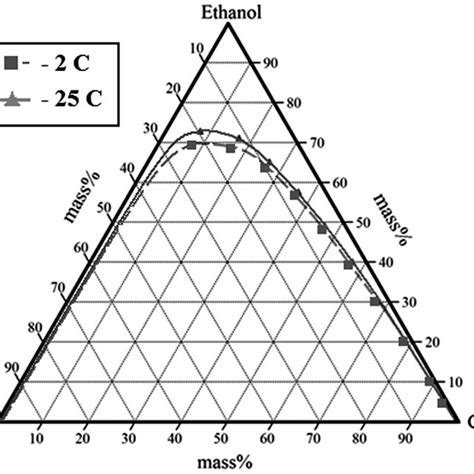

4. Address Ethanol-Blended Fuels

Ethanol, commonly found in modern gasoline (E10, E15), is hygroscopic, meaning it attracts and absorbs water. This can lead to “phase separation,” where the ethanol and water mixture separates from the gasoline and sinks to the bottom of the tank, forming a corrosive sludge. This water-ethanol mix can corrode engine parts and leave the remaining gasoline with a lower octane rating. If possible, use non-ethanol gasoline for small engines or equipment that will sit idle for long periods. If using ethanol-blended fuel, specific stabilizers designed to combat ethanol’s effects are essential.

5. Implement a Fuel Rotation Schedule and Inspection

Even with stabilizers and proper storage, fuel has a finite shelf life. For critical applications, implementing a rotation schedule is wise. Use older fuel first and replace it with fresh fuel regularly. For gasoline, aim to rotate every 6-12 months if possible, and for diesel, every 12-24 months, depending on the stabilizer used and storage conditions. Regularly inspect stored fuel for signs of degradation, such as discoloration, cloudiness, or a sour smell. If found, it’s best to dispose of it properly and refill with fresh, treated fuel.

Conclusion: Preserve Your Power Source

Preventing stored fuel degradation is a multi-faceted approach that combines the right additives, proper storage environment, and diligent management. By understanding the vulnerabilities of gasoline and diesel and proactively implementing these strategies, you can ensure your emergency power, recreational vehicles, and essential equipment are always ready to perform, avoiding the frustration and expense of degraded fuel.