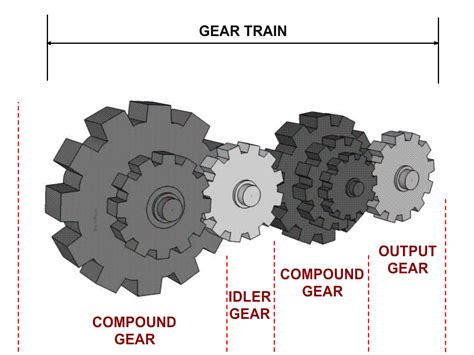

Introduction: The Evolving Landscape of Gear Materials

For centuries, steel has been the undisputed champion of gear manufacturing, revered for its exceptional strength, durability, and load-bearing capacity. However, as industries push the boundaries of performance, efficiency, and environmental considerations, composite materials have emerged as viable alternatives. While steel gears remain the default for high-stress, high-temperature, and high-torque applications, composite gears offer compelling advantages under specific operating conditions where their unique properties can significantly enhance system performance and reduce operational costs.

Defining the Players: Steel vs. Composite Gears

Steel Gears: Typically made from carbon steel, alloy steel, or stainless steel, these gears are known for their high tensile strength, wear resistance, and ability to withstand significant shock loads. They often require lubrication and can be heavy, noisy, and susceptible to corrosion in certain environments.

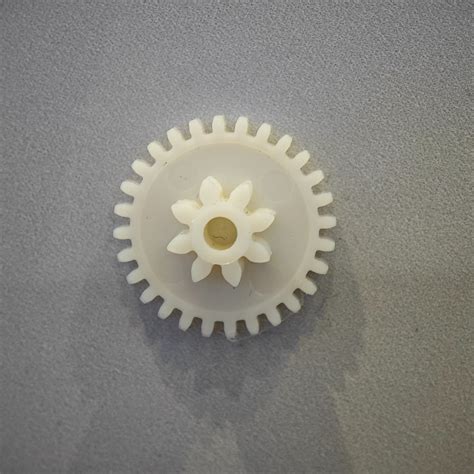

Composite Gears: These gears are manufactured from a matrix material (e.g., nylon, PEEK, acetal, polyester) reinforced with fibers (e.g., glass, carbon, aramid). This combination yields materials with tailored properties that can include high strength-to-weight ratios, excellent damping characteristics, and chemical inertness.

Specific Operating Conditions Favoring Composite Gears

1. Weight Reduction and Inertia Minimization

In applications where every gram counts, or where rapid acceleration and deceleration are critical, composite gears offer a significant advantage. Being considerably lighter than steel, they reduce the overall mass of the system, leading to:

- Improved Energy Efficiency: Less power is required to move and stop lighter components.

- Faster Response Times: Lower inertia allows for quicker changes in speed and direction.

- Reduced Wear on Supporting Components: Lighter gears place less stress on bearings, shafts, and motors.

This is particularly valuable in aerospace, robotics, drone technology, automotive (electric vehicles), and high-speed automation.

2. Noise and Vibration Damping

Steel gears, especially when running unlubricated or at high speeds, can generate considerable noise and vibration. Composite materials inherently possess superior damping characteristics compared to metals. Choosing composite gears can lead to:

- Quieter Operation: Essential for applications in medical devices, consumer appliances (e.g., washing machines, printers), office equipment, and automotive interiors.

- Reduced Wear: Less vibration can extend the life of surrounding components.

- Improved User Comfort: In human-centric applications, noise reduction is a key benefit.

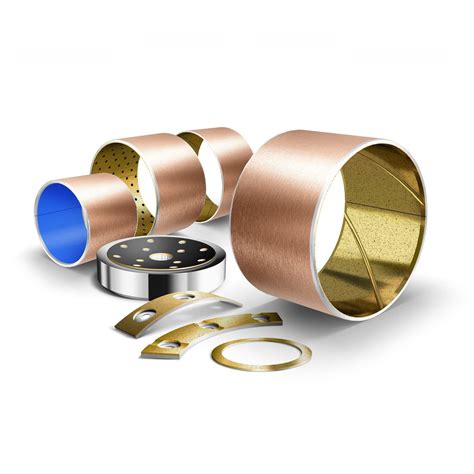

3. Corrosion and Chemical Resistance

In environments exposed to moisture, chemicals, or aggressive cleaning agents, steel gears (even stainless steel in some cases) can corrode, leading to degradation and failure. Many engineering plastics used in composite gears are highly resistant to:

- Acids, Bases, and Solvents: Ideal for chemical processing plants.

- Water and Humidity: Perfect for marine applications, food processing equipment, and outdoor machinery.

- Sterilization Processes: Crucial for medical and pharmaceutical devices that undergo frequent cleaning and sterilization.

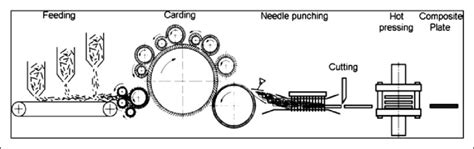

4. Self-Lubrication and Reduced Maintenance

Certain composite materials, particularly those with internal lubricants (like PTFE or molybdenum disulfide), can operate effectively with little to no external lubrication. This is a critical advantage in situations where:

- Lubrication is Inconvenient or Impossible: Inaccessible locations, sealed units.

- Contamination is a Concern: Food and beverage industry, cleanrooms, medical equipment, textile machinery where oil could spoil products.

- Maintenance Needs to Be Minimized: Remote equipment or consumer goods designed for long, maintenance-free operation.

5. Electrical and Thermal Insulation

Unlike conductive steel, many composite materials are excellent electrical insulators. This property is vital in applications such as:

- Electrical Equipment: Where gear components need to prevent current flow or arcing.

- Electronic Devices: Protecting sensitive electronics from electromagnetic interference.

Additionally, their lower thermal conductivity can be beneficial in applications where heat transfer needs to be limited between components.

6. Cost-Effectiveness in Mass Production and Complex Geometries

For high-volume production, composite gears made via injection molding can be significantly more cost-effective than machining steel gears. Injection molding allows for:

- Rapid Production: High throughput and lower per-unit cost.

- Complex Geometries: Intricate designs and integrated features (like hubs or spokes) can be molded in a single step, reducing assembly and post-processing.

While the material cost of some high-performance composites can be higher than steel, the overall manufacturing and assembly cost savings can make them the more economical choice.

Conclusion: A Strategic Material Choice

The decision to choose a composite gear over a steel gear is not about one material being inherently superior to the other, but rather about selecting the optimal material for the specific demands of an application. While steel remains indispensable for extreme load and temperature conditions, composite gears excel where properties like light weight, quiet operation, chemical resistance, self-lubrication, electrical insulation, and cost-effective mass production are paramount. As material science advances, the range of applications where composite gears provide a strategic advantage continues to expand, driving innovation across numerous industries.